A person of us (Levi) functions with semiconductors and the other (Aeppli) with X-rays. So, immediately after pondering this issue, we deemed applying X-rays to nondestructively impression chips. You’d want to go over and above the resolution utilized in medical X-ray scanners. But it was clear to us that the desired resolution was attainable. At that second, what we’ve been calling the “chip scan” challenge was born.

Our initially approach, ptychographic X-ray computed tomography, was examined first on a part of a 22-nanometer Intel processor developing a thorough 3D graphic of the chip’s interconnects.SLS-USC Chip-Scan group

Several a long time later, we’ve manufactured it attainable to map the overall interconnect construction of even the most highly developed and complex processors with out destroying them. Right now, that procedure normally takes a lot more than a working day, but advancements about the up coming handful of a long time ought to permit the mapping of whole chips inside hrs.

This technique—called ptychographic X-ray laminography—requires obtain to some of the world’s most powerful X-ray mild resources. But most of these amenities are, conveniently, situated shut to where by substantially of the innovative chip style and design comes about. So as obtain to this procedure expands, no flaw, failure, or fiendish trick will be in a position to conceal.

Soon after selecting to go after this method, our first order of small business was to set up what condition-of-the-art X-ray techniques could do. That was accomplished at the Paul Scherrer Institute (PSI) in Switzerland, exactly where 1 of us (Aeppli) performs. PSI is dwelling to the Swiss Light Resource (SLS) synchrotron, a single of the 15 brightest sources of coherent X-rays crafted so significantly.

Coherent X-rays differ from what is utilized in a healthcare or dental business office in the same way that the highly collimated beam of gentle from a laser pointer differs from light emitted in all instructions from an incandescent bulb. The SLS and very similar amenities generate highly coherent beams of X-ray photons by first accelerating electrons just about to the pace of gentle. Then, magnetic fields deflect those electrons, inducing the creation of the preferred X-rays.

To see what we could do with the SLS, our multidisciplinary staff acquired an Intel Pentium G3260 processor from a community keep for about US $50 and eradicated the packaging to expose the silicon. (This CPU was made making use of 22-nanometer CMOS FinFET know-how).

https://www.youtube.com/check out?v=h_gbDn5Te70

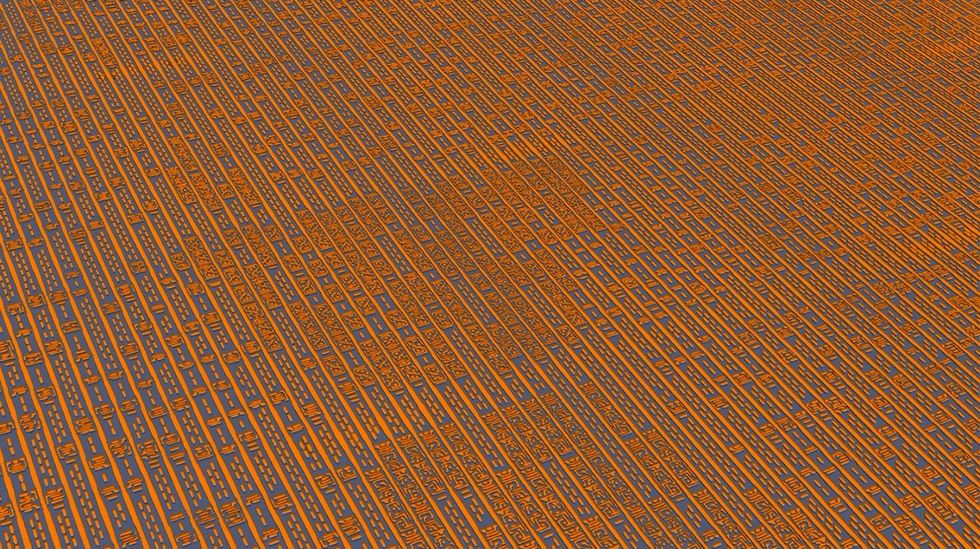

A fly-though of the top rated layers of an Intel 22-nanometer processor reconstructed from X-ray scans.SLS-USC Chip-Scan Workforce

Like all these chips, the G3260’s transistors are made of silicon, but it is the arrangement of metal interconnects that hyperlink them up to sort circuits. In a modern processor, interconnects are constructed in a lot more than 15 levels, which from over seem like a map of a city’s avenue grid. The lessen levels, closer to the silicon, have amazingly fantastic characteristics, spaced just nanometers aside in today’s most state-of-the-art chips. As you ascend the interconnect layers, the functions come to be sparser and even bigger, until you attain the best, where electrical get hold of pads join the chip to its deal.

We commenced our evaluation by chopping out a 10-micrometer-huge cylinder from the G3260. We experienced to acquire this damaging phase since it drastically simplified factors. 10 micrometers is much less than 50 percent the penetration depth of the SLS’s photons, so with a thing this compact we’d be capable to detect ample photons passing by means of the pillar to decide what was inside of.

We positioned the sample on a mechanical stage to rotate it about its cylindrical axis and then fired a coherent beam of X-rays via the aspect. As the sample rotated, we illuminated it with a pattern of overlapping 2-µm-extensive places.

At each illuminated location, the coherent X-rays diffracted as they handed by the chip’s tortuous tower of copper interconnects, projecting a sample onto a detector, which was saved for subsequent processing. The recorded projections contained enough information about the material by which the X-rays traveled to identify the construction in three proportions. This strategy is termed ptychographic X-ray computed tomography (PXCT). Ptychography is the computational method of generating an graphic of some thing from the interference sample of light through it.

The underlying principle driving PXCT is rather easy, resembling the diffraction of light by means of slits. You may possibly recall from your introductory physics course that if you shine a coherent beam of gentle as a result of a slit onto a distant plane, the experiment generates what is termed a Fraunhofer diffraction pattern. This is a sample of mild and dark bands, or fringes, spaced proportionally to the ratio of the light’s wavelength divided by the width of the slit.

If, rather of shining gentle by way of a slit, you shine it on a pair of carefully spaced objects, kinds so modest that they are properly points, you will get a unique pattern. It does not subject where by in the beam the objects are. As very long as they stay the exact same length from every single other, you can go them all over and you’d get the exact pattern.

By them selves, neither of these phenomena will enable you reconstruct the tangle of interconnects in a microchip. But if you blend them, you are going to commence to see how it could get the job done. Set the pair of objects in the slit. The ensuing interference sample is derived from the diffraction owing to a mix of slit and object, revealing facts about the width of the slit, the length between the objects, and the relative position of the objects and the slit. If you move the two factors a little bit, the interference sample shifts. And it’s that shift that makes it possible for you to calculate specifically wherever the objects are inside of the slit.

Any genuine sample can be taken care of as a set of pointlike objects, which give rise to sophisticated X-ray scattering patterns. This sort of designs can be utilized to infer how these pointlike objects are organized in two dimensions. And the principle can be utilised to map things out in three dimensions by rotating the sample in the beam, a approach identified as tomographic reconstruction.

You require to make certain you’re established up to accumulate adequate details to map the structure at the essential resolution. Resolution is determined by the X-ray wavelength, the dimensions of the detector, and a handful of other parameters. For our original measurements with the SLS, which used .21-nm-wavelength X-rays, the detector had to be placed about 7 meters from the sample to arrive at our target resolution of 13 nm.

In March 2017, we shown the use of PXCT for nondestructive imaging of built-in circuits by publishing some pretty very 3D photos of copper interconnects in the Intel Pentium G3260 processor. Those illustrations or photos reveal the 3-dimensional character and complexity of electrical interconnects in this CMOS built-in circuit. But they also captured attention-grabbing particulars such as the imperfections in the metallic connections concerning the levels and the roughness involving the copper and the silica dielectric close to it.

From this proof-of-principle demonstration on your own, it was clear that the technique had prospective in failure assessment, design validation, and excellent handle. So we employed PXCT to probe equally sized cylinders cut from chips designed with other companies’ technologies. The aspects in the ensuing 3D reconstructions were being like fingerprints that were being exceptional to the ICs and also exposed substantially about the manufacturing procedures used to fabricate the chips.

We had been inspired by our early good results. But we understood we could do superior, by building a new form of X-ray microscope and coming up with more successful strategies to increase picture reconstruction utilizing chip style and manufacturing info. We known as the new technique PyXL, shorthand for ptychographic X-ray laminography.

The initial factor to offer with was how to scan a full 10-millimeter-wide chip when we had an X-ray penetration depth of only around 30 µm. We solved this difficulty by very first tilting the chip at an angle relative to the beam. Next, we rotated the sample about the axis perpendicular to the plane of the chip. At the same time we also moved it sideways, raster fashion. This allowed us to scan all pieces of the chip with the beam.

At every single minute in this system, the X-rays passing through the chip are scattered by the components inside of the IC, generating a diffraction sample. As with PXCT, diffraction patterns from overlapping illumination places comprise redundant information and facts about what the X-rays have passed as a result of. Imaging algorithms then infer a construction that is the most dependable with all calculated diffraction styles. From these we can reconstruct the interior of the complete chip in 3D.

Useless to say, there is a great deal to get worried about when developing a new sort of microscope. It have to have a stable mechanical structure, such as precise motion phases and posture measurement. And it should record in detail how the beam illuminates every single location on the chip and the ensuing diffraction patterns. Obtaining practical solutions to these and other difficulties necessary the efforts of a team of 14 engineers and physicists. The geometry of PyXL also needed building new algorithms to interpret the info collected. It was really hard perform, but by late 2018 we experienced successfully probed 16-nm ICs, publishing the effects in October 2019.

Today’s cutting-edge processors can have interconnects as tiny as 30 nm aside, and our procedure can, at least in theory, generate illustrations or photos of structures more compact than 2 nm.

In these experiments, we were being in a position to use PyXL to peel away every layer of interconnects pretty much to expose the circuits they sort. As an early exam, we inserted a small flaw into the style file for the interconnect layer closest to the silicon. When we when compared this version of the layer with the PyXL reconstruction of the chip, the flaw was immediately evident.

In theory, a handful of days of function is all we’d will need to use PyXL to receive significant data about the integrity of an IC produced in even the most innovative services. Today’s chopping-edge processors can have interconnects just tens of nanometers aside, and our strategy can, at the very least in principle, deliver images of constructions lesser than 2 nm.

The new variation of our X-ray strategy, known as ptychographic X-ray laminography, can uncover the interconnect composition of complete chips without having detrimental them, even down to the smallest constructions [top]. Working with that strategy, we could effortlessly find out a (deliberate) discrepancy amongst the layout file and what was manufactured [bottom].

But elevated resolution does choose more time. Though the hardware we’ve developed has the capacity to absolutely scan an space up to 1.2 by 1.2 centimeters at the greatest resolution, accomplishing so would be impractical. Zooming in on an location of fascination would be a greater use of time. In our original experiments, a reduced-resolution (500-nm) scan more than a square portion of a chip that was .3 mm on a aspect took 30 hours to obtain. A substantial-resolution (19-nm) scan of a a lot smaller sized portion of the chip, just 40 μm broad, took 60 hrs.

The imaging price is essentially restricted by the X-ray flux out there to us at SLS. But other amenities boast increased X-ray fluxes, and techniques are in the works to strengthen X-ray resource “brilliance”—a mix of the amount of photons produced, the beam’s spot, and how immediately it spreads. For illustration, the MAX IV Laboratory in Lund, Sweden, pioneered a way to strengthen its brilliance by two orders of magnitude. A further more one particular or two orders of magnitude can be obtained by indicates of new X-ray optics. Combining these advancements should just one working day enhance full flux by a factor of 10,000.

With this better flux, we ought to be capable to achieve a resolution of 2 nm in much less time than it now normally takes to get hold of 19-nm resolution. Our method could also study a one-square-centimeter integrated circuit—about the sizing of an Apple M1 processor—at 250-nm resolution in fewer than 30 hours.

And there are other strategies of boosting imaging pace and resolution, these types of as far better stabilizing the probe beam and improving our algorithms to account for the style and design principles of ICs and the deformation that can outcome from way too considerably X-ray publicity.

While we can now notify a good deal about an IC from just the layout of its interconnects, with further advancements we really should be ready to discover all the things about it, which include the resources it’s produced of. For the 16-nm-technology node, that includes copper, aluminum, tungsten, and compounds identified as silicides. We could even be able to make local measurements of strain in the silicon lattice, which arises from the multilayer producing procedures desired to make slicing-edge devices.

Pinpointing elements could grow to be significantly essential, now that copper-interconnect know-how is approaching its boundaries. In up to date CMOS circuits, copper interconnects are susceptible to electromigration, exactly where current can kick copper atoms out of alignment and bring about voids in the framework. To counter this, the interconnects are sheathed in a barrier materials. But these sheaths can be so thick that they go away minimal space for the copper, creating the interconnects as well resistive. So option resources, these kinds of as cobalt and ruthenium, are becoming explored. For the reason that the interconnects in query are so fine, we’ll need to have to reach sub-10-nm resolution to distinguish them.

There is reason to feel we’ll get there. Implementing PXCT and PyXL to the “connectome” of both equally components and wetware (brains) is 1 of the important arguments researchers all over the globe have designed to guidance the development of new and upgraded X-ray sources. In the meantime, do the job carries on in our laboratories in California and Switzerland to create superior components and program. So someday before long, if you are suspicious of your new CPU or curious about a competitor’s, you could make a fly-by tour by means of its internal workings to make confident all the things is truly in its appropriate position.

The SLS-USC Chip-Scan Staff contains Mirko Holler, Michal Odstrcil, Manuel Guizar-Sicairos, Maxime Lebugle, Elisabeth Müller, Simone Finizio, Gemma Tinti, Christian David, Joshua Zusman, Walter Unglaub, Oliver Bunk, Jörg Raabe, A. F. J. Levi, and Gabriel Aeppli.

This article seems in the May possibly 2022 print challenge as “The Naked Chip.”